Chimney

A chimney is a structure for venting hot flue gases or smoke from a boiler, stove, furnace or fireplace to the outside atmosphere. Chimneys are typically vertical, or as near as possible to vertical, to ensure that the gases flow smoothly, drawing air into the combustion in what is known as the stack, or chimney, effect. The space inside a chimney is called a flue. Chimneys may be found in buildings, steam locomotives and ships. In the United States, the term smokestack (colloquially, stack) is also used when referring to locomotive chimneys or ship chimneys, and the term funnel can also be used.[1][2]

The height of chimneys plays a role in their ability to transfer flue gases using stack effect, the dispersion of pollutants at higher altitude helps to ease down its influence on surroundings. In the case of chemically aggressive output, the tall chimney allows partial or complete self-neutralization of chemicals in the air before they reach the ground. The dispersion of pollutants over greater area reduces their concentrations in compliance with regulatory limits.

Contents |

History

Romans used tubes inside the walls to draw smoke out of bakeries but real chimneys appeared only in northern Europe in the 12th century. Industrial chimneys became common in the late 18th century. The earliest extant example of an English chimney is at the keep of Conisbrough Castle in Yorkshire, which dates from 1185 AD.[3]

Chimneys have traditionally been built of brick, both in small and large buildings. Early chimneys were of a simple brick construction. Later chimneys were constructed by placing the bricks around tile liners. To control downdrafts venting caps (often called chimney pots) with a variety of designs are sometimes placed on the top of chimneys.

In the eighteenth and nineteenth centuries, the methods used to extract lead from its ore produced large amounts of toxic fumes. In the north of England, long near-horizontal chimneys were built, often more than 3 km (2 mi) long, which typically terminated in a short vertical chimney in a remote location where the fumes would cause less harm. Lead and silver deposits formed on the inside of these long chimneys, and periodically workers would be sent along the chimneys to scrape off these valuable deposits.

Construction

Due to brick's limited ability to handle transverse loads, chimneys in houses were often built in a "stack", with a fireplace on each floor of the house sharing a single chimney, often with such a stack at the front and back of the house. Today's central heating systems have made chimney placement less critical, and the use of non-structural gas vent pipe allows a flue gas conduit to be installed around obstructions and through walls.

In fact, many modern high-efficiency heating appliances do not require a chimney. Such appliances are typically installed near an outside wall, and a noncombustible wall thimble allows vent pipe to be run directly through the outside wall.

Industrial chimneys are commonly referred to as flue gas stacks and are typically external structures, as opposed to being built into the wall of a building. They are generally located adjacent to a steam-generating boiler or industrial furnace and the gases are carried to it with ductwork. Today the use of reinforced concrete has almost entirely replaced brick as a structural component in the construction of industrial chimneys. Refractory bricks are often used as a lining, particularly if the type of fuel being burned generates flue gases containing acids. Modern industrial chimneys sometimes consist of a concrete windshield with a number of flues on the inside.

The 300 metre chimney at Sasol Three consists of a 26 metre diameter windshield with four 4.6 metre diameter concrete flues which are lined with refractory bricks built on rings of corbels spaced at 10 metre intervals. The reinforced concrete can be cast by conventional formwork or sliding formwork. The height is to ensure the pollutants are dispersed over a wider area to meet legislative or safety requirements.

Chimney pots

A chimney pot is placed on top of the chimney to inexpensively extend the length of the chimney, and to improve the chimney's draft. A chimney with more than one pot on it indicates that there is more than one fireplace on different floors sharing the chimney.

A chimney cowl is placed on top of the chimney to prevent birds and squirrels from nesting in the chimney. They often feature a rain guard to keep rain from going down the chimney. A metal wire mesh is often used as a spark arrestor to minimize burning debris from rising out of the chimney and making it onto the roof. Although the masonry inside the chimney can absorb a large amount of moisture which later evaporates, rainwater can collect at the base of the chimney. Sometimes weep holes are placed at the bottom of the chimney to drain out collected water.

A chimney cowl or wind directional cap is helmet shaped chimney cap that rotates to align with the wind and prevent a backdraft of smoke and wind back down the chimney.

An H-style cap (cowl) is a chimney top constructed from chimney pipes shaped like the letter H. It is an age old method to regulate draft in situations where prevailing winds or turbulences cause down draft and backpuffing. Although the H cap has a distinctive advantage over most other downdraft caps, it fell out of favor because of its bulky looks. It is found mainly in marine use but has been gaining popularity again due to its energy saving functionality. The H-cap stabilizes the draft rather than increasing it. Other down draft caps are based on the Venturi effect, solving downdraft problems by increasing the up draft constantly resulting in much higher fuel consumption.

A chimney damper is a metal spring door placed at the top of the chimney with a long metal chain that allows one to open and close the chimney from the fireplace.

In the late Middle Ages in Western Europe the design of crow-stepped gables arose to allow maintenance access to the chimney top, especially for tall structures such as castles and great manor houses.

Chimney draught or draft

- (See the Flue gas stack article for more details)

When coal, oil, natural gas, wood or any other fuel is combusted in a stove, oven, fireplace, hot water boiler or industrial furnace, the hot combustion product gases that are formed are called flue gases. Those gases are generally exhausted to the ambient outside air through chimneys or industrial flue gas stacks (sometimes referred to as smokestacks).

The combustion flue gases inside the chimneys or stacks are much hotter than the ambient outside air and therefore less dense than the ambient air. That causes the bottom of the vertical column of hot flue gas to have a lower pressure than the pressure at the bottom of a corresponding column of outside air. That higher pressure outside the chimney is the driving force that moves the required combustion air into the combustion zone and also moves the flue gas up and out of the chimney. That movement or flow of combustion air and flue gas is called "natural draught/draft", "natural ventilation", "chimney effect", or "stack effect". The taller the stack, the more draught or draft is created. There can be cases of diminishing returns: if a stack is overly tall in relation to the heat being sent out of the stack, the flue gases may cool before reaching the top of the chimney. This condition can result in poor drafting, and in the case of wood burning appliances, the cooling of the gases prior to exiting the chimney can cause creosote to condense near the top of the chimney. The creosote can restrict the exit of flue gases and may pose a fire hazard.

Designing chimneys and stacks to provide the correct amount of natural draught or draft involves a number design factors, many of which require iterative trial-and-error methods.

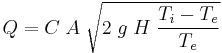

As a "first guess" approximation, the following equation can be used to estimate the natural draught/draft flow rate by assuming that the molecular mass (i.e., molecular weight) of the flue gas and the external air are equal and that the frictional pressure and heat losses are negligible:

| where: | |

| Q | = chimney draught/draft flow rate, m³/s |

|---|---|

| A | = cross-sectional area of chimney, m² (assuming it has a constant cross-section) |

| C | = discharge coefficient (usually taken to be from 0.65 to 0.70) |

| g | = gravitational acceleration, 9.807 m/s² |

| H | = height of chimney, m |

| Ti | = average temperature inside the chimney, K |

| Te | = external air temperature, K. |

Combining two flows into chimney: At+Af<A, where At=7.1 inch2 is the minimum required flow area from water heater tank and Af=19.6 inch2 is the minimum flow area from a furnace of a central heating system.

Maintenance and problems

A characteristic problem of chimneys is they develop deposits of creosote on the walls of the structure when used with wood as a fuel. Deposits of this substance can interfere with the airflow and more importantly, they are flammable and can cause dangerous chimney fires if the deposits ignite in the chimney. Thus, it is recommended — and in some countries even mandatory — that chimneys be inspected annually and cleaned on a regular basis to prevent these problems. The workers who perform this task are called chimney sweeps. This work used to be done largely by child labour, and as such features in Victorian literature. In the Middle Ages in some parts of Europe, a crow-stepped gable design was developed, partly to provide access to chimneys without use of ladders.

Masonry (brick) chimneys have also proved particularly susceptible to crumbling during earthquakes. Government housing authorities in quake-prone cities like San Francisco and Los Angeles now recommend building new homes with stud-framed chimneys around a metal flue. Bracing or strapping old masonry chimneys has not proved to be very effective in preventing damage or injury from earthquakes. It is now possible to buy "faux-brick" facades to cover these modern chimney structures.

Liners have been standard in new construction for years, but they're lacking in old structures whose masonry has not been restored and updated. Tile liners help keep flue gases where they belong. They isolate combustible building materials from high heat, and they prevent creosote and other by-products of combustion from seeping through porous brick and mortar.[4]

Other problems include "spalling" brick, in which moisture seeps into the brick and then freezes, cracking and flaking the brick and loosening mortar seals.

Dual-use chimneys

Some very high chimneys are used for carrying antennas of mobile phone services and low power FM/TV-transmitters. Special attention must be paid to possible corrosion problems if these antennas are near the exhaust of the chimney.

In some cases the chimneys of power stations are used also as pylons. However this type of construction, which is used at several power stations in the former Soviet Union, is not very common, because of corrosion problems of conductor cables.

The Dům Dětí a Mládeže v Modřanech in Prague, Czech Republic is equipped with an observation deck.

The chimney of Pei Tou Incinerator carries a revolving restaurant.

Cooling tower used as an industrial chimney

At some power stations, which are equipped with plants for the removal of sulfur dioxide and nitrogen oxides, it is possible to use the cooling tower as a chimney. Such cooling towers can be seen in Germany at the Power Station Staudinger Grosskrotzenburg and at the Power Station Rostock. At power stations that are not equipped for removing sulfur dioxide, such usage of cooling towers could result in serious corrosion problems.

Notable chimneys

| Chimney | Year | Country | Town | Pinnacle height | Remarks | |

|---|---|---|---|---|---|---|

| GRES-2 Power Station | 1987 | Kazakhstan | Ekibastusz | 420 m | 1378 ft | Tallest chimney in the World[5] |

| Inco Superstack | 1971 | Canada | Copper Cliff | 385 m | 1263 ft | |

| Kennecott Smokestack | 1978 | United States of America | Garfield, Utah | 370 m | 1215 ft | |

| Berezovskaya GRES | 1985 | Russia | Sharypovo | 370 m | 1214 ft | |

| Trbovlje Chimney | 1976 | Slovenia | Trbovlje | 360 m | 1181 ft | |

| Thermal Power Station Kakanj, Catici | 1988 | Bosnia and Herzegovina | Kakanj | 300 m | 985 ft | |

| Sagardighi Thermal Power Station | 2004 | India | Sagardighi, Murshidabad | 275 m | 902 ft | |

| Drax Power Station | 1973 | United Kingdom | Selby | 259 m | 850 ft | |

| MVM Észak-Buda Power Station | 1974 | Hungary | Budapest | 203 m | 666 ft | |

| Anaconda Smelter Stack | 1919 | United States of America | Anaconda, Montana | 178 m | 585 ft | Tallest freestanding brick chimney |

| The Windscale Pile Chimneys | 1957 | United Kingdom | Windscale, Cumbria | 124m | 406 ft | |

| Chimney Edstein | 2008 | Republic of China | Taichung, Taiwan | 180 m | 550 ft | |

| Pei Tou Incinerator chimney | Republic of China | Taipei, Taiwan | 150 m | 492 ft | ||

See also

- Chimney fire

- Cooling tower

- Count Rumford

- Flue gas stack

- List of tallest chimneys in the world

- Nitrogen oxide sensor

- Santa Claus

- Stack effect

- Silos & Smokestacks National Heritage Area

References

- ^ C.F. Saunders (1923), The Southern Sierras of California

- ^ Jules Verne (1872), Around the World in Eighty Days

- ^ James Burke, Connections (Little, Brown and Co.) 1978/1995, ISBN 0-316-11672-6, p. 159

- ^ Bringing an old chimney up to par

- ^ Diagram of 25 tallest flue gas stacks worldwide

External links

- CICIND - International Committee on Industrial Chimneys

- Chimney Safety Institute of America

- Power Station Konakovskaya GRES, at which chimneys serve as electricity pylons

- Article about chimney breast removal

- Chimney Maintenance Information

- European Chimney Association ECA; to find further information on chimneys

- National Association of Chimney Engineers; UK trade association for the chimney engineering industry